Your Reliable Curing Agents Manufacturers

We provide a range of curing agents—including TGIC, HAA, and epoxy types—specifically formulated to ensure stable crosslinking in powder-coating systems. They are critical for achieving the required performance in high-durability architectural coatings, appliance finishes, general industrial uses, and protective films.

Request A QuotePCOTEC Core Advantages

Stable Crosslinking

Wide Cure Window

Enhanced Durability

Consistent Film Quality

System Flexibility

Sustainability

Main Products

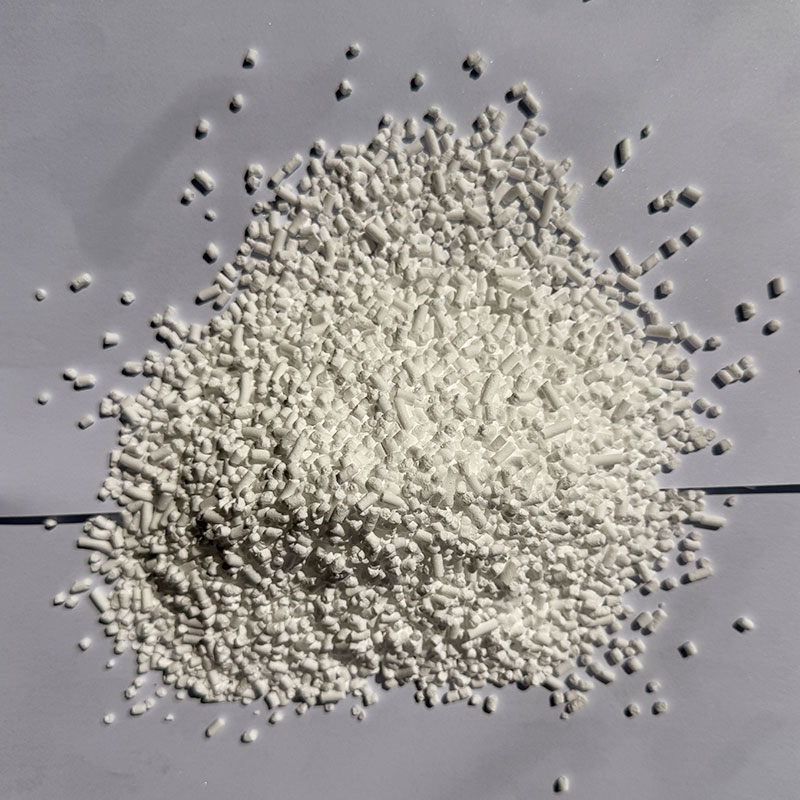

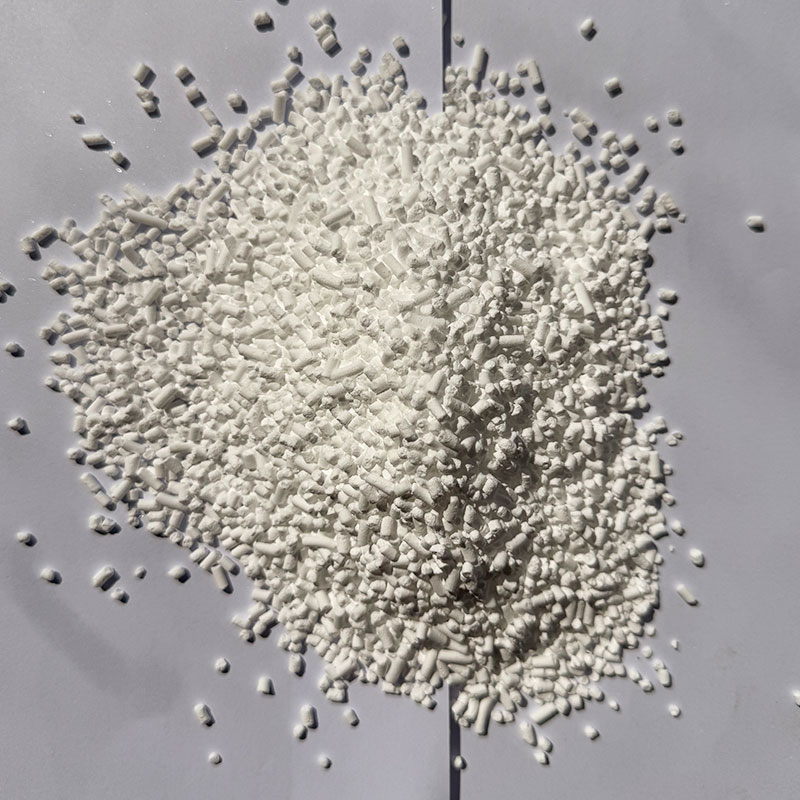

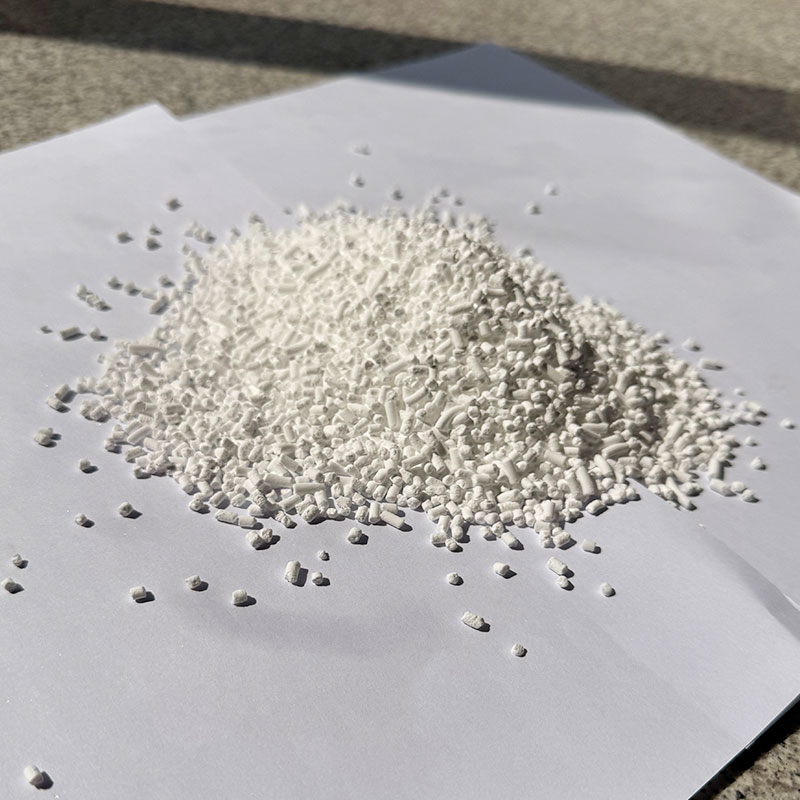

TGIC

Curing Agents

TGIC (Triglycidyl Isocyanurate) is a heterocyclic epoxy compound with a molecular weight of 297 (CAS No.: 2451-62-9). It exhibits excellent heat resistance, weather resistance, adhesion, and high-temperature performance.

●Crosslinking agent for pure polyester powder coatings. Dosage is calculated based on the acid value of the polyester resin.

●Crosslinking agent for carboxyl-containing polyacrylate (PA). Typical dosage: 7% of resin weight (adjusted by acid value)

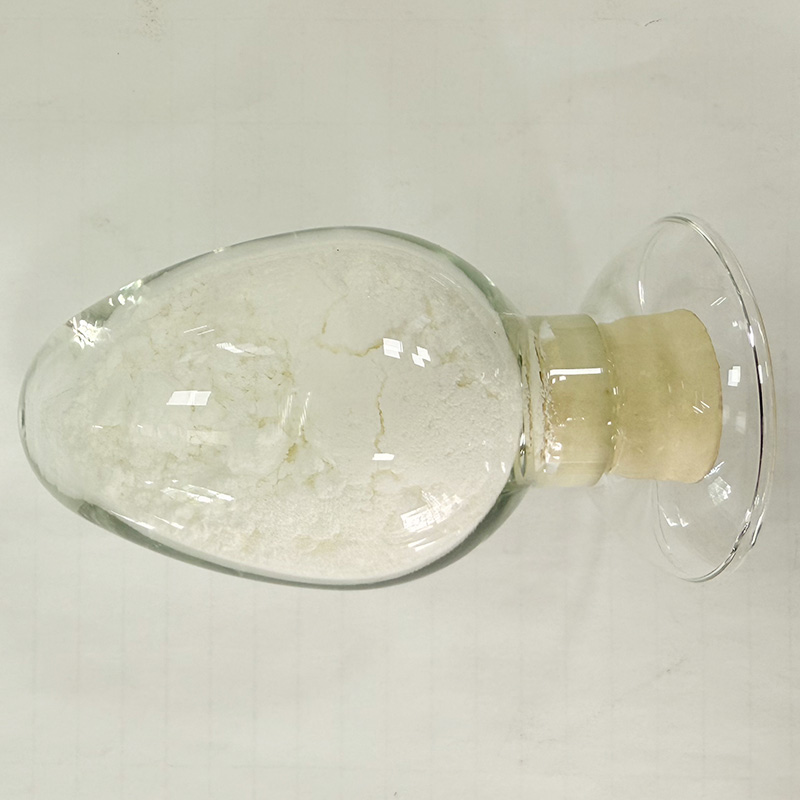

HAA

Curing Agents

HAA are tetra-functional β-hydroxyalkylamide (HAA) compounds with excellent mechanical and weather resistance properties. They crosslink with carboxylated polyester or acrylic resins to produce non-toxic, skin-friendly, and environmentally friendly outdoor weather-resistant powder coatings, offering a safer alternative to TGIC.

Our advantage

Proven Material Expertise

Certified Quality & Traceability

Technical Customization & Application Support

Sustainable Chemistry Commitment

Global Supply & Reliable Service

Key Applications

FAQ Use & Operation

How Do Curing Agents Influence The Flow, Leveling, And Final Appearance Of Powder Coatings?

Curing agents determine the crosslinking speed and melt viscosity during the curing stage. If the reactivity is too fast, the coating may gel prematurely, causing orange peel or poor leveling. If too slow, the film may sag or show surface defects. We provide curing agents with balanced reaction kinetics to match your resin system and achieve smooth, uniform appearance.

Can You Help Tailor The Curing Ratio for My Production Line?

Absolutely. We provide recommended stoichiometric ratios, reaction-kinetics support, and resin–curing-agent matching to ensure stable processing at your target line speed and oven temperature.

How Do Curing Agents Affect Yellowing Resistance And Long-Term Durability?

Curing-agent structure directly influences thermal stability and UV performance. We design and select curing agents with optimized crosslink architecture to minimize yellowing and improve outdoor durability.

Are Your Curing Agents Suitable for Both Standard And Low-Temperature Curing Systems?

Yes. We offer curing agents with different activation energies, allowing formulations to cure at conventional 180–200°C or energy-saving 140–160°C depending on application needs.

What Should I Do If My Powder Coating Has Incomplete Cure Or under-Baking Issues?

Our team can evaluate curing-agent reactivity, resin compatibility, cure-window design, and oven parameters to optimize the formulation and ensure full crosslinking.

How Do You Ensure Consistent Reactivity Of Your Curing Agents?

We control purity, particle size, and reaction-endpoint parameters during synthesis, and test each batch for reactivity index to ensure predictable curing behavior in TGIC and HAA systems.