Your Reliable Fillers Manufacturers

Achieve superior opacity, strength, stability, and cost-effectiveness in your powder coatings with our tailored filler solutions. Our range includes titanium dioxide, precipitated/ultrafine barium sulfate, light calcium carbonate, and silica micro powder, each selected to perfect your formulation.

Request A QuotePCOTEC Core Advantages

High Opacity Boost

Reinforced Film Strength

Thermal Stability Aid

Rheology Optimization

Improved Processing Flow

Sustainability

Main Products

Benzoin

Fillers

Benzoin is an essential degassing agent used in powder coatings (e.g., appliances, automotive parts) to prevent pinholes and surface defects during curing. With high purity and a melting range of 133–137°C, it vaporizes at the appropriate stage of the curing process, effectively releasing trapped gases from the film. Its degassing action ensures:

● Enhanced aesthetic quality

● Improved corrosion resistance

● Reduced rework/scrap rates

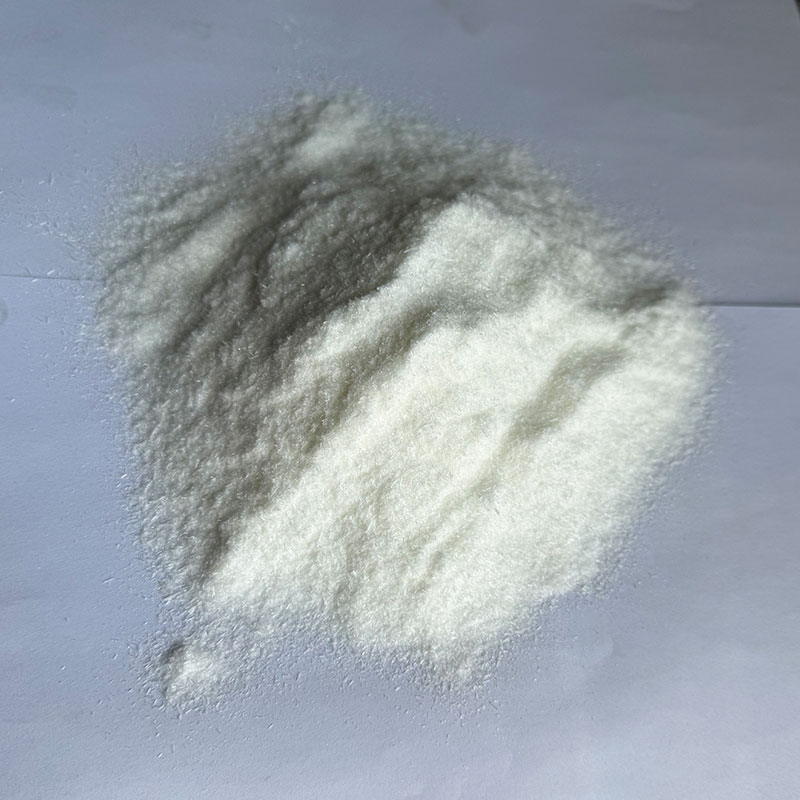

Titanium Dioxide

Fillers

Titanium dioxide is a high-purity white inorganic material known for its exceptional opacity and brightness in powder coatings. It offers strong UV stability, excellent whiteness retention, and consistent hiding performance, making it essential for achieving durable, clean, and visually uniform film appearance in demanding applications.

Our advantage

Proven Material Expertise

Certified Quality & Traceability

Technical Customization & Application Support

Sustainable Chemistry Commitment

Global Supply & Reliable Service

Key Applications

FAQ Use & Operation

What Causes Fillers To Introduce Porosity, Pinholes, Or Micro-Defects?

Moisture-containing fillers, improper drying, or incompatible surface treatments can release gases during curing, creating pinholes or porosity. Dry, surface-treated fillers help maintain a smooth film.

Can You Recommend Filler Types And Loading Levels for Different Powder Coating Systems?

Yes. We suggest optimized filler types (barium sulfate, calcium carbonate, talc, etc.) and loading levels based on gloss target, mechanical performance, cost requirements, and compatibility with TGIC, HAA, hybrid, or special-effect formulations.

How Do Fillers Affect Outdoor Durability And Weather Resistance?

Fillers with poor UV stability or high reactivity may accelerate chalking or color fading. UV-stable, inert fillers—combined with optimized resin–pigment systems—help improve long-term outdoor performance.

Do Fillers Impact Curing Behavior Or Crosslinking Efficiency?

Yes. Certain fillers may absorb curing heat or interfere with melt flow, slowing cure speed or causing incomplete crosslinking. Selecting thermally stable fillers and optimizing filler loading prevents these issues.

Why Does Filler Dispersion Affect Coating Mechanical Strength?

Poorly dispersed fillers can create weak points within the film, reducing impact resistance and flexibility. Uniform dispersion enhances mechanical balance and improves the overall film integrity.

How Do Fillers Influence Gloss And Surface Appearance in Powder Coatings?

Fillers affect surface smoothness and gloss by altering the resin’s melt viscosity and flow behavior. Fine-particle fillers can reduce gloss, while coarser fillers may create texture. Proper particle-size control and resin compatibility ensure consistent appearance.