What Is An Indoor Physical Matting Agent?

An indoor physical matting agent is a functional powder coating additive used to reduce surface gloss and create a controlled matte finish in indoor coating systems. Unlike chemical matting approaches that rely on Resin consumption or reaction interference, a physical matting agent achieves gloss reduction through its physical structure and dispersion behavior within the coating film.

In indoor powder coatings, appearance uniformity, color stability, and processing cleanliness are critical. An indoor physical matting agent is designed to lower gloss without causing yellowing, smoke generation, or unwanted chemical side effects during curing. It allows formulators to achieve predictable matte levels while maintaining coating integrity and stable production conditions.

Table of Contents

- Technical indicators of PCOTEC Indoor Physical Matting Agent

- How an indoor physical matting agent works

- Advantages of indoor physical matting agents

- Typical applications in indoor powder coatings

- Formulation and processing considerations

- Comparison with chemical matting approaches

- Selection considerations for buyers

- Why PCOTEC supports reliable indoor matting solutions

- Storage and handling recommendations

- FAQ

- Conclusion

Technical indicators of PCOTEC Indoor Physical Matting Agent

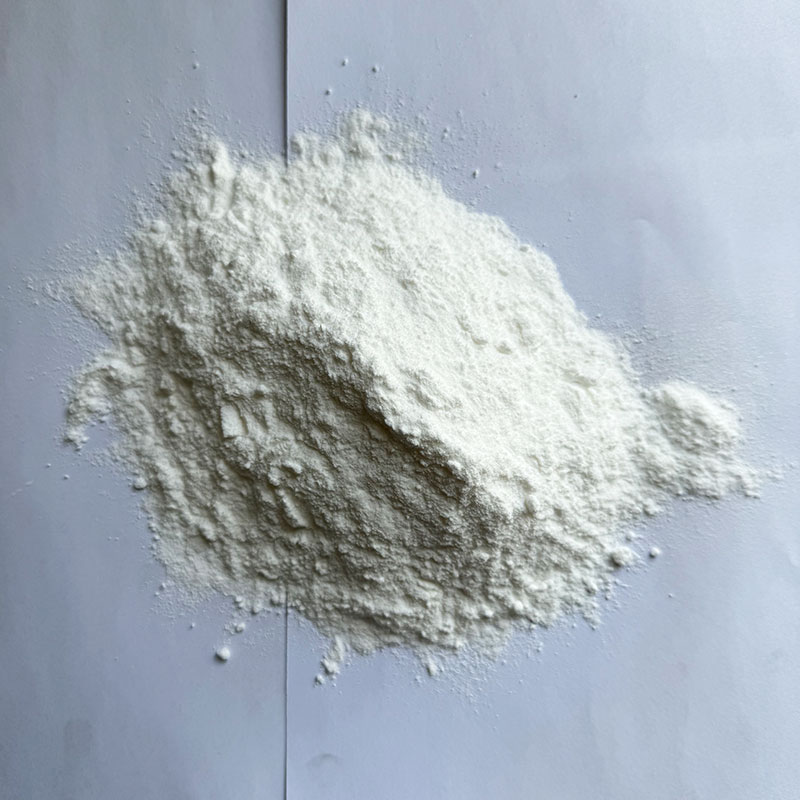

This indoor physical matting agent is supplied as a stable powder additive suitable for controlled matte finishes in epoxy and epoxy-polyester powder coating systems.

| Item | Specification |

|---|---|

| Appearance | Light yellow powder |

| Bulk density | Stable at 550–560 grams per liter |

Bulk density stability supports consistent feeding and dispersion during powder production, while controlled particle characteristics contribute to reliable matting performance and surface uniformity.

How an indoor physical matting agent works

A physical matting agent functions by creating micro-level surface roughness within the cured coating film. During melting and flow, the matting particles distribute evenly throughout the coating. As the film cures, these particles subtly disrupt surface smoothness at a microscopic level, reducing light reflection and lowering gloss.

This indoor physical matting agent does not consume epoxy resin during curing and does not participate in chemical crosslinking. Because of this, it avoids common side effects associated with some chemical matting methods, such as resin imbalance, discoloration, or smoke formation during baking.

Key functional characteristics include:

Gloss reduction through physical surface modulation

Stable dispersion without interfering with curing reactions

Consistent matting effect across the coating surface

Clean processing behavior during extrusion and curing

Advantages of indoor physical matting agents

Stable color and appearance control

Because the matting effect is achieved physically rather than chemically, this type of matting agent does not cause yellowing during curing. This is particularly important for light-colored or neutral indoor finishes where color accuracy is closely monitored.

Clean curing behavior

The product does not produce smoke during use, supporting a cleaner curing environment and reducing contamination risk within ovens and surrounding equipment.

Predictable matting performance

This matting agent can provide at least three distinct degrees of matting effect, allowing formulators to fine-tune gloss levels based on application needs while maintaining surface consistency.

Cost-efficient matte formulation

Compared with other matting approaches, physical matting agents often provide a more economical solution for achieving matte finishes, especially in high-volume indoor coating programs.

Typical applications in indoor powder coatings

Indoor physical matting agents are commonly used where matte appearance, visual consistency, and clean processing are required.

Typical application scenarios include:

Indoor metal furniture and fixtures

Office equipment and storage systems

Electrical enclosures and cabinets used indoors

Decorative interior components

General indoor industrial parts requiring low-gloss finishes

These applications prioritize stable appearance and processing efficiency rather than extreme weather resistance.

Formulation and processing considerations

When incorporating an indoor physical matting agent into a powder coating formulation, several factors influence final appearance and performance.

Recommended evaluation steps include:

Selecting target gloss level

Define the desired matte range and visual texture before formulation adjustment.Balancing matting level and film integrity

Excessive matting agent can affect mechanical properties or surface feel, so dosage optimization is important.Ensuring uniform dispersion

Proper mixing and extrusion conditions help distribute matting particles evenly and avoid gloss variation.Verifying performance across thickness range

Matte consistency should be checked at different film builds to confirm uniform appearance.Confirming color stability after curing

Light-colored coatings should be evaluated carefully to verify absence of yellowing.

Comparison with chemical matting approaches

Physical matting agents differ from chemical matting systems in several important ways:

No epoxy consumption during curing

No smoke generation during baking

No yellowing associated with chemical reaction byproducts

More predictable gloss control through dosage adjustment

For indoor applications where appearance consistency and clean processing are priorities, physical matting agents are often preferred.

Selection considerations for buyers

When selecting an indoor physical matting agent, buyers typically focus on:

Appearance stability and color neutrality

Bulk density consistency for production control

Ease of dispersion during extrusion

Matting efficiency and gloss control range

Cost balance relative to target performance

Lab trials and small-scale production runs remain the best method for confirming compatibility with specific resin systems and process conditions.

Why PCOTEC supports reliable indoor matting solutions

PCOTEC focuses on supplying functional powder coating Additives designed for real production environments. Indoor physical matting agents provided by PCOTEC are developed to support stable gloss control, clean processing behavior, and consistent batch performance.

Key strengths include:

Clear technical indicators that support formulation planning

Stable bulk density for reliable handling and dispersion

Clean curing behavior without smoke or yellowing

Practical support for matte finish optimization

PCOTEC works with customers to align matting performance with appearance goals and production efficiency.

Storage and handling recommendations

To maintain consistent performance, proper storage is recommended.

Store in a dry, indoor environment

Protect from moisture and direct sunlight

Keep packaging sealed when not in use

Follow standard inventory rotation practices

Stable storage conditions help preserve powder flowability and matting efficiency.

FAQ

Is an indoor physical matting agent suitable for outdoor coatings?

This type of matting agent is designed primarily for indoor powder coatings. Outdoor applications usually require additional weather resistance considerations.

Does it affect curing speed or crosslinking?

No. It does not participate in curing reactions and does not consume epoxy resin.

Can it be used with epoxy and epoxy-polyester systems?

Yes. It is commonly evaluated in epoxy and epoxy-polyester powder coating formulations intended for indoor use.

How many gloss levels can be achieved?

This product can provide at least three degrees of matting effect, depending on formulation design and dosage.

Conclusion

An indoor physical matting agent is a powder coating additive used to achieve controlled matte finishes through physical surface modification rather than chemical reaction. It supports stable gloss reduction, avoids yellowing and smoke generation, and offers a cost-efficient solution for indoor powder coating systems.

PCOTEC supplies an indoor physical matting agent with stable bulk density and clean processing behavior, helping coating manufacturers achieve consistent matte appearance while maintaining efficient and reliable production.