Application Trend Analysis of Methylphenyl Silicone Resin in High-Heat-Resistant Coatings

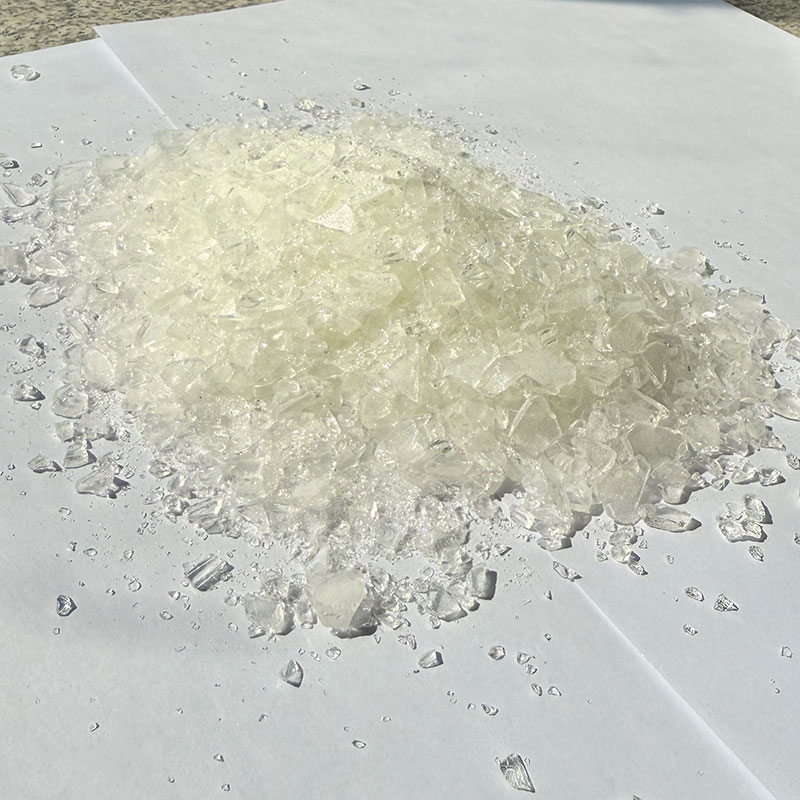

Methylphenyl silicone Resin is an organosilicon resin with a siloxane backbone and incorporated methyl and phenyl groups, possessing both high reactivity and excellent thermal stability. Its molecules contain a controllable proportion of silanol groups, allowing the resin to participate in various crosslinking and curing systems and to be stably blended with organic resins such as polyesters, epoxies, and acrylics. By adjusting the ratio of phenyl to methyl groups, silanol content, and molecular weight range, the temperature resistance limit, weather resistance, and flexibility can be precisely controlled.

PCOTEC, as a supplier of Silicone Resins, can customize continuous heat resistance levels, curing reaction speeds, and compatibility systems according to different working conditions, meeting the diverse application needs of powder coatings and industrial high-temperature coatings.

Table of Contents

- Growing Demand for High-Temperature and Weather-Resistant Coatings

- Structural Advantages and Heat Resistance Mechanism

- Applications in Powder Coating Systems

- Role in Industrial Heat-Resistant Coatings

- Shift Toward Multi-Performance Optimization

- Customization at the Supply Level

- Overall Market Outlook

- Frequently Asked Questions

Growing Demand for High-Temperature and Weather-Resistant Coatings

As industrial equipment, high-temperature components, and functional powder coatings continue to face more demanding service environments, requirements for heat resistance and long-term weather stability are steadily increasing. Under this trend, methylphenyl Silicone Resin has gradually become a key modification material in high-heat-resistant coating systems.

This type of silicone resin features a siloxane backbone combined with methyl and phenyl functional groups. The molecular structure provides a well-balanced combination of thermal stability, chemical reactivity, and compatibility with conventional coating systems, making it suitable for enhancing performance in a wide range of thermosetting coatings.

Structural Advantages and Heat Resistance Mechanism

Compared with traditional organic resins, methylphenyl silicone resin can participate in crosslinking reactions through silanol groups without significantly compromising original application properties. Once incorporated into the coating network, the siloxane structure improves thermal stability and helps maintain structural integrity under elevated temperatures.

Both laboratory studies and industrial practice indicate that when the effective silicone resin content reaches a certain threshold, coatings can achieve a noticeable increase in continuous heat resistance. Under long-term thermal cycling conditions, these coatings typically exhibit lower weight loss and more stable surface appearance, reflecting improved resistance to thermal degradation.

Applications in Powder Coating Systems

In powder coatings, methylphenyl silicone resin is commonly blended with polyester, epoxy, or acrylic systems. By adjusting the ratio of phenyl to methyl groups, formulators can fine-tune the balance between heat resistance and flexibility.

Different molecular weight ranges and silicon content levels directly influence key properties such as glass transition temperature, crosslink density, and aging behavior. This tunability gives the resin significant design flexibility across different temperature-resistance grades, from medium-heat applications to high-performance thermal coatings.

Role in Industrial Heat-Resistant Coatings

Industrial heat-resistant coatings represent another major application area for methylphenyl silicone resin. In environments such as high-temperature equipment housings, exhaust systems, and heat-treatment installations, the silicone-based network formed by this resin helps mitigate the effects of high-temperature oxidation and thermal fatigue.

Through formulation-level structural optimization, it is possible to balance heat resistance with processing adaptability, allowing coatings to meet the performance demands of various operating conditions without sacrificing application efficiency.

Shift Toward Multi-Performance Optimization

As application scenarios become more specialized, market expectations for silicone resins are evolving. Performance evaluation is no longer limited to a single heat-resistance metric but increasingly includes compatibility, application stability, and long-term weathering behavior.

Thanks to the adjustable molecular structure of methylphenyl silicone resin, performance customization for specific coating systems has become an important industry direction. This adaptability allows formulators to optimize multiple properties simultaneously rather than making trade-offs between heat resistance and processability.

Customization at the Supply Level

From a supply perspective, targeted performance design can be achieved by adjusting parameters such as silicon content, silanol concentration, molecular weight distribution, and phenyl substitution degree. These variables directly affect heat resistance range, curing reaction rate, and long-term coating stability.

This performance-driven customization approach enables downstream users to upgrade coating properties without making major changes to existing formulations, reducing development time and minimizing secondary formulation costs.

Overall Market Outlook

Overall, the application scope of methylphenyl silicone resin in high-temperature and weather-resistant coatings continues to expand. As demand for high-performance coatings grows, its technical value in powder coatings, industrial protective coatings, and functional material systems is expected to become increasingly prominent.

Frequently Asked Questions

Is methylphenyl silicone resin only suitable for high-temperature applications?

While its primary advantage lies in high-temperature resistance, adjusting the phenyl content and silanol level allows this resin to perform effectively in medium-temperature or weather-resistant coating systems as well. PCOTEC can tailor performance based on the target temperature range, rather than limiting use to extreme heat conditions.

Does the addition level significantly affect coating performance?

Yes, the addition level directly influences heat resistance and crosslink density. An effective solid content of at least 15 percent is generally recommended. For extreme high-temperature environments, higher addition levels combined with structural optimization can deliver more stable thermal performance.

How does it differ from other silicone resins?

Methylphenyl silicone resin combines the heat resistance of phenyl groups with the flexibility of methyl groups. Compared with pure methyl silicone resins, it offers higher temperature resistance. Compared with high-phenyl systems, it provides better processing adaptability, making it suitable for formulations that require balanced overall performance.

Will it affect coating application properties?

Within a reasonable molecular weight range, its influence on flow and curing behavior is controllable. Through molecular structure customization and optimized addition methods, heat resistance and weatherability can be enhanced while maintaining an acceptable application window.

Can grades be customized for specific customer systems?

Yes. We can customize different grades of resin based on the customer's base resin type, curing conditions, and target performance requirements. By adjusting silicon content, molecular weight, and reactivity, stable compatibility with existing systems can be achieved while avoiding additional formulation modification costs.