What Are TGIC Curing Agents Used For?

TGIC Curing Agents are crosslinkers used primarily in powder coating systems to build a durable, tightly bonded coating film after baking. In most practical formulations, TGIC reacts with carboxyl-functional polyester Resins to create a stable three-dimensional network. This network is the foundation for key coating outcomes that buyers care about, including mechanical strength, adhesion, outdoor durability, and heat stability. When TGIC grade selection and formulation ratios are well matched, the coating can achieve a controlled balance between flow and leveling, appearance consistency, and long-term performance.

At PCOECT, TGIC curing agent supply focuses on consistency in mass production and grade selection that aligns with downstream performance targets. By controlling core quality indicators and offering different positioning grades, we help powder coating producers build systems that perform reliably across different substrates, climates, and production lines.

Table of Contents

- 1. The primary use: Crosslinking carboxyl polyester powder coatings

- 2. Another important use: Crosslinking carboxyl acrylic powder coatings

- 3. What TGIC helps powder coatings achieve in real applications

- 4. How to determine TGIC dosage in a practical way

- 5. PCOECT TGIC curing agent grades and typical positioning

- 6. Typical industries and parts that rely on TGIC curing agents

- 7. Storage and handling practices that protect TGIC performance

- Conclusion

1. The primary use: Crosslinking carboxyl polyester powder coatings

The most common use of TGIC curing agents is as the crosslinker for TGIC polyester powder coating systems. In this route, TGIC provides epoxy functional groups that react with carboxyl groups on the polyester resin during curing. The result is a dense and stable crosslinked structure that supports:

Film hardness and abrasion resistance for handling and service wear

Strong adhesion to properly pretreated metal substrates

Outdoor weather resistance and stable appearance under UV and humidity

Heat resistance performance that depends on the resin design and crosslink density

Controlled leveling and surface uniformity when melt flow and curing rate are balanced

This is why TGIC is widely used in general outdoor powder coatings as well as performance-oriented architectural and industrial applications.

2. Another important use: Crosslinking carboxyl acrylic powder coatings

TGIC is also used as a crosslinker for carboxyl acrylic powder coating systems. Acrylic-based powder coatings often prioritize appearance and surface performance, and TGIC provides a reliable reaction partner for building a strong network.

Typical formulation logic:

TGIC dosage is determined based on the resin acid value and the targeted curing behavior

A commonly referenced starting point in many acrylic systems is around 7 percent of resin weight, then adjusted based on acid value and performance targets

In real production, the key is not the nominal percentage but whether the system cures consistently at the line’s baking window while maintaining flow and film integrity.

3. What TGIC helps powder coatings achieve in real applications

TGIC curing agents are chosen because they support a combination of performance outcomes that are difficult to achieve simultaneously if the curing system is unstable.

Mechanical strength that stays consistent across batches

A stable TGIC crosslinking reaction helps deliver predictable film hardness and impact resistance when matched with the resin acid value. This is especially valuable for products where coating failures lead to high rework cost.

Weather resistance for outdoor exposure

For outdoor powder coatings, TGIC systems are widely used to maintain coating integrity under UV, moisture, and temperature cycling. Film durability and surface stability are directly linked to the crosslinked network quality.

Corrosion protection through film integrity and adhesion

TGIC itself is not a corrosion inhibitor, but by building a strong network and supporting adhesion, it helps coatings maintain a sealed, stable film that protects the substrate when the full formulation is designed correctly.

Leveling and appearance control

In powder coating, appearance defects often come from imbalance between melt flow, viscosity, and curing speed. TGIC curing agents are used because they can support strong performance while still allowing the system to be tuned for smooth leveling.

4. How to determine TGIC dosage in a practical way

TGIC dosage is typically linked to the acid value of the resin and the target cure schedule. The goal is to match epoxy functionality to available carboxyl groups, then fine-tune based on processing behavior and final performance requirements.

A practical approach:

Start from the resin acid value and stoichiometric balance

Validate extrusion stability and powder storage behavior

Confirm curing completeness under the actual oven profile

Evaluate mechanical performance, appearance stability, and weathering direction tests

Adjust TGIC level to reduce under-cure risk while avoiding over-crosslinking that may reduce flexibility

This is where consistent TGIC quality matters, because unstable epoxy value or impurity variation can widen the trial window and create batch-to-batch uncertainty.

5. PCOECT TGIC curing agent grades and typical positioning

PCOECT offers TGIC curing agents positioned for different powder coating objectives, with controlled quality indicators that support formulation stability.

TGIC curing agent reference overview

| Model | Appearance | Epoxy Equivalent(g/mol) | Total Chlorine Percent(%) | Melting Range(°C) | Viscosity(120±1°C, mPa·s) | Volatile Percent (%) | Epichlorohydrin (ppm) | Features | Typical use |

|---|---|---|---|---|---|---|---|---|---|

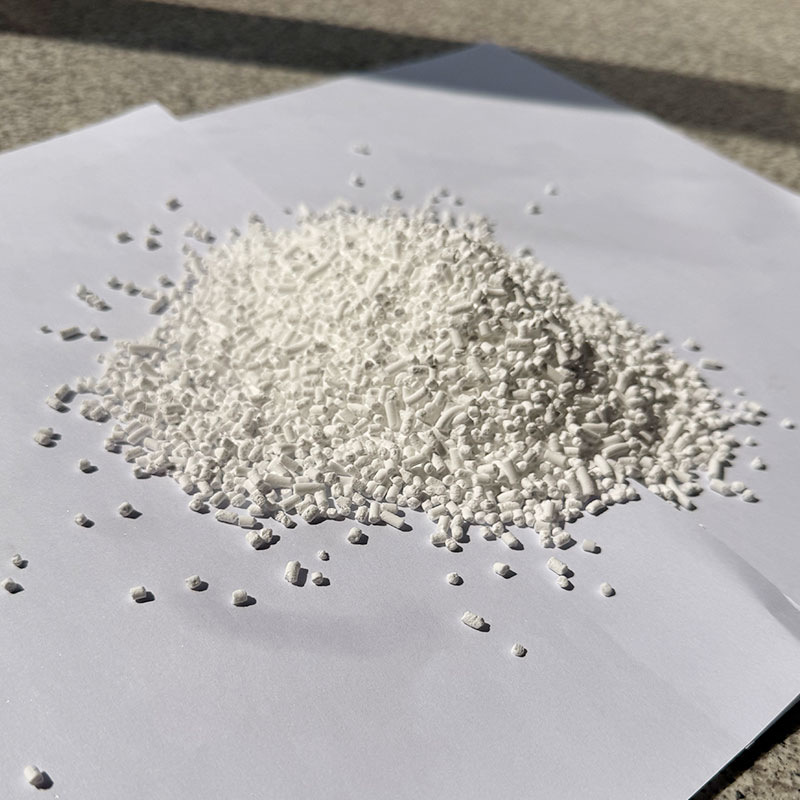

| TK-902 | White granular or powder | 110 max | 0.6 max | 95 to 125 | 100 max | 0.5 max | 250 max | High cost performance, general-purpose | General outdoor powder coatings, indoor powder coatings |

| TK-906 | White granular or powder | 105 max | 0.4 max | 95 to 125 | 100 max | 0.5 max | 100 max | High performance, strong weathering direction, improved safety control | Super weather-resistant outdoor powders, high-end white or light color outdoor powders, applications requiring higher mechanical and durability performance |

How to use this table in selection:

If the project prioritizes broad compatibility and cost-performance for common powder coating products, a general-purpose positioning is typically sufficient.

If the project targets outdoor durability, higher performance stability, stricter impurity control, and better control on appearance retention in demanding environments, a higher-performance grade is more suitable.

6. Typical industries and parts that rely on TGIC curing agents

TGIC curing agents are used across powder coating markets where durability, appearance, and production efficiency must be balanced.

Common examples:

Architectural aluminum profiles and outdoor metal building components

Outdoor structures and metal fixtures exposed to sun and humidity

Vehicle-related metal parts where coating durability is required

PV mounting brackets and outdoor support structures

High-end appliances and equipment housings that demand consistent finish and mechanical stability

Agricultural machinery where impact resistance and outdoor durability are both important

For white and light-color outdoor powder coatings, higher requirement systems often focus on long-term appearance stability, and the curing agent quality and impurity control become more sensitive selection factors.

7. Storage and handling practices that protect TGIC performance

To maintain consistent processing behavior and reactivity, TGIC curing agents should be stored and managed under stable conditions.

Recommended handling logic:

Use sealed inner packaging to reduce moisture exposure

Store in a dry, cool area and avoid direct heat and sunlight

Maintain good moisture control in warehouse and production environments

Rotate inventory and manage shelf life carefully for consistent production batches

A practical reference for standard packaging and storage:

Typical packaging can be 25 kg per bag with protective inner lining

Standard shelf life is commonly designed around one year under proper room-temperature storage conditions

Stable storage is not only about keeping the curing agent usable, but also about keeping extrusion behavior and curing repeatability consistent across time.

Conclusion

TGIC curing agents are used mainly as crosslinkers in carboxyl polyester and carboxyl acrylic powder coating systems. Their core function is to build a stable crosslinked network that supports mechanical strength, adhesion, outdoor durability, and controlled appearance. In real production, TGIC selection should match resin acid value, processing conditions, and the targeted performance level, because curing speed, melt flow, and film structure must work together to deliver consistent results.

At PCOECT, the value we provide is not only supplying TGIC curing agents, but supplying grades with controlled quality indicators and clear positioning. This helps powder coating producers reduce process variability, stabilize batch performance, and meet different market requirements from general-purpose coatings to higher-demand outdoor systems.

Previous: What Is HAA Curing Agents Used For?