What Are The Top 5 Uses Of Polyester Resin In Industrial Coatings?

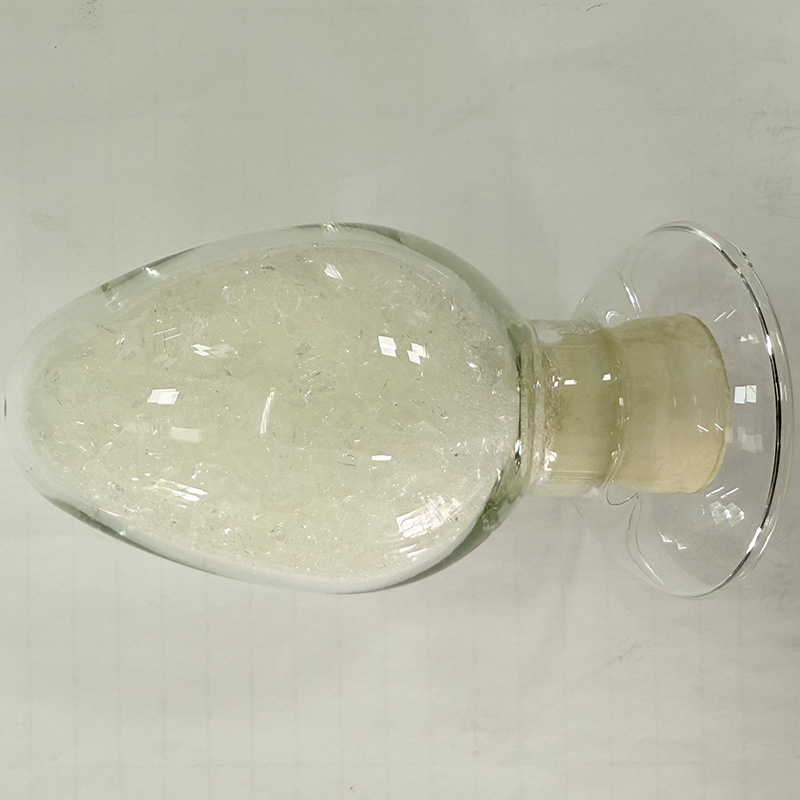

Polyester Resin is one of the most widely used film-forming binders in modern thermosetting coating systems, especially powder coatings. Its value comes from a rare combination of properties that matter in real production: strong weathering performance, stable gloss and color retention, good mechanical strength, and dependable chemical resistance when the system is formulated and cured correctly. For industrial users, polyester resin also offers broad formulation flexibility, making it easier to target specific cure windows, appearance levels, and durability requirements without over-complicating the line.

This article explains the top five industrial uses of polyester resin in coatings, why polyester is chosen in each case, and how to select the right polyester system for your environment. To see available options, browse the PCOTEC Resin Range and the PCOTEC Polyester Resin Application Systems.

Table of Contents

- Why Polyester Resin Is A Workhorse Binder In Industrial Coatings

- Use 1: Architectural Aluminum Extrusions And Facade Components

- Use 2: Outdoor Metal Components And Furniture Systems

- Use 3: Home Appliance And Consumer Durable Finishes

- Use 4: Industrial Equipment, Enclosures, And General Metal Protection

- Use 5: Anti-Corrosion Systems And Protective Barrier Coatings

- Choosing The Right Polyester Resin System For The Job

- Quick Reference Table: Matching Uses To Polyester Resin Priorities

- Conclusion

Why Polyester Resin Is A Workhorse Binder In Industrial Coatings

In coating design, the binder determines how the film forms, how it crosslinks during cure, and how it resists degradation over time. Polyester resin is commonly selected because it can be engineered for:

Long-term weathering resistance and gloss stability for outdoor exposure

Strong mechanical durability such as hardness, abrasion resistance, and impact flexibility balance

Practical chemical resistance for many industrial fluids, detergents, and mild solvents

Wide appearance options from matte to high gloss with consistent flow and leveling

Efficient production, including systems designed for stable curing windows and repeatable film build

In short, polyester resin is less about a single feature and more about dependable total performance across a wide range of industrial coating demands.

Use 1: Architectural Aluminum Extrusions And Facade Components

Architectural aluminum profiles, window frames, curtain walls, louvers, and metal rail systems are a top use case for polyester resin because outdoor exposure stresses a coating in multiple ways at once. UV radiation, thermal cycling, humidity, and airborne contaminants can quickly reveal weaknesses in a binder. Polyester-based powder coatings are widely used here because they maintain appearance longer, supporting gloss and color stability while providing a protective barrier against corrosion.

In architectural projects, selection should focus on weatherability, color retention, and edge coverage. A strong polyester system helps reduce early chalking and fading, while also offering the mechanical resilience needed for installation handling. For project consistency, the most successful architectural programs standardize resin system, pretreatment method, and cure schedule so the same durability is achieved across multiple batches and sites.

Use 2: Outdoor Metal Components And Furniture Systems

Outdoor metal parts such as fences, gates, garden hardware, exterior brackets, and furniture frames often face a combination of UV exposure, rain, temperature swings, and abrasion. Polyester resin is a common choice because it delivers a balanced film that resists weathering while staying tough enough for daily contact and movement.

The coating performance in this category depends heavily on how the film handles micro-cracking and edge wear. Polyester systems that maintain flexibility while keeping sufficient hardness help reduce coating damage at welds, corners, and bolt areas. For products that will be moved and stacked, impact resistance and surface durability should be evaluated together, not separately. Many manufacturers also prioritize appearance consistency here, because outdoor goods are often sold in fixed color lines that must match across production seasons.

Use 3: Home Appliance And Consumer Durable Finishes

Appliance panels and consumer durable parts demand a clean appearance, stable color, and resistance to common household chemicals such as detergents and cleaners. Polyester resin is frequently used because it supports smooth film formation, good mechanical durability, and practical chemical resistance for day-to-day contact.

In appliance finishing, the resin system is often chosen for consistent flow, stable gloss control, and reduced defect sensitivity at typical production film builds. Polyester-based coatings are also valued for their ability to support varied aesthetics including textured finishes, matte surfaces, and high-gloss looks without sacrificing durability. For suppliers serving multiple appliance models, a consistent polyester system can simplify qualification across product lines while keeping the finish stable in mass production.

Use 4: Industrial Equipment, Enclosures, And General Metal Protection

Industrial equipment housings, electrical enclosures, machinery guards, racks, and frames require a coating that can resist abrasion, handling damage, and periodic chemical contact, while remaining visually uniform. Polyester resin is widely used because it provides a strong backbone that supports mechanical strength, hardness, and long-term durability across typical industrial environments.

This category often rewards coating systems that are forgiving in production. Polyester resin can be formulated to achieve stable cure behavior and reliable film properties even when part geometry varies and line loading changes. When the goal is repeatable performance for bulk order manufacturing, selecting a resin system with a practical cure window and consistent flow helps reduce rejects, rework, and color variation.

Use 5: Anti-Corrosion Systems And Protective Barrier Coatings

Polyester resin also plays a major role in corrosion protection systems, particularly when paired with correct surface pretreatment and a formulation designed for barrier performance. While epoxy can deliver very strong chemical resistance in many conditions, polyester systems are often chosen when the environment includes outdoor exposure and long-term appearance retention is required alongside protection.

For anti-corrosion performance, the system approach matters. Resin selection should consider the exposure profile, film thickness control, edge protection, and the compatibility of primers and topcoats if a multi-layer system is used. Polyester resin can support durable protective coatings that resist moisture ingress and maintain coating integrity over time, especially when application and cure conditions are well controlled.

Choosing The Right Polyester Resin System For The Job

Polyester resin performance is strongly influenced by the curing chemistry used in the coating system. Different curing routes can shift the balance between outdoor durability, chemical resistance, color stability, and processing behavior.

A practical selection view:

TGIC-cured polyester systems are often selected when long-term outdoor durability and robust overall performance are priority.

HAA-cured polyester systems are often selected when a TGIC-free route is preferred and when a balanced finish and processing profile is needed.

Urethane polyester systems are often considered where high appearance quality and strong outdoor durability are required, depending on the specific performance targets and line conditions.

The right answer depends on your substrate, pretreatment, cure temperature profile, and the actual chemical exposures your coating must survive.

Quick Reference Table: Matching Uses To Polyester Resin Priorities

| Industrial Use | What To Prioritize In The Resin System | What To Validate In Production |

|---|---|---|

| Architectural Aluminum | Weathering, color and gloss stability, edge protection | Pretreatment control, cure consistency, exterior durability targets |

| Outdoor Components | UV resistance, flexibility-hardness balance, abrasion durability | Impact resistance, scratch performance, stable color match across batches |

| Appliances | Appearance consistency, detergent resistance, clean flow | Defect control, gloss stability, film build consistency |

| Industrial Equipment | Mechanical durability, stable curing window, practical chemical resistance | Line robustness, adhesion on real geometry, recoat and touch-up behavior |

| Anti-Corrosion | Barrier performance, film integrity, long-term durability | Salt and moisture resistance, edge coverage, system compatibility if multilayer |

For OEM and ODM programs, it is often more effective to standardize a small number of qualified polyester systems and tune them by Additives and cure schedule, rather than switching resin families frequently. This approach improves repeatability and simplifies scale supply planning.

Conclusion

Polyester resin is widely used in industrial coatings because it combines weathering durability, appearance stability, mechanical strength, and practical chemical resistance in a binder that can be tuned for many end-use scenarios. The top five uses are architectural aluminum, outdoor metal components, appliance finishes, industrial equipment coatings, and anti-corrosion protective systems. The best-performing projects treat resin selection as a system decision, aligning resin type, curing route, pretreatment, and cure schedule for repeatable production results.

To explore more polyester resin options and recommended system pathways, please browse the PCOTEC Resin Range. For selection support, share your substrate, exposure conditions, and cure profile with PCOTEC. Our team can recommend suitable resin systems and practical formulation directions to match your performance targets and production requirements.