Your Reliable Resin Manufacturers

We supply silicone, polyester, and epoxy resins for high-performance powder-coating systems. These resins are widely used in various applications, including general industry, appliances, architectural components, wear-resistant coatings.

Request A QuotePCOTEC Core Advantages

Film-Forming Backbone

Polymer Network Stability

Mechanical Strength Base

Thermal Performance Control

Chemical Resistance Matrix

Sustainability

Main Products

Silicone Resin

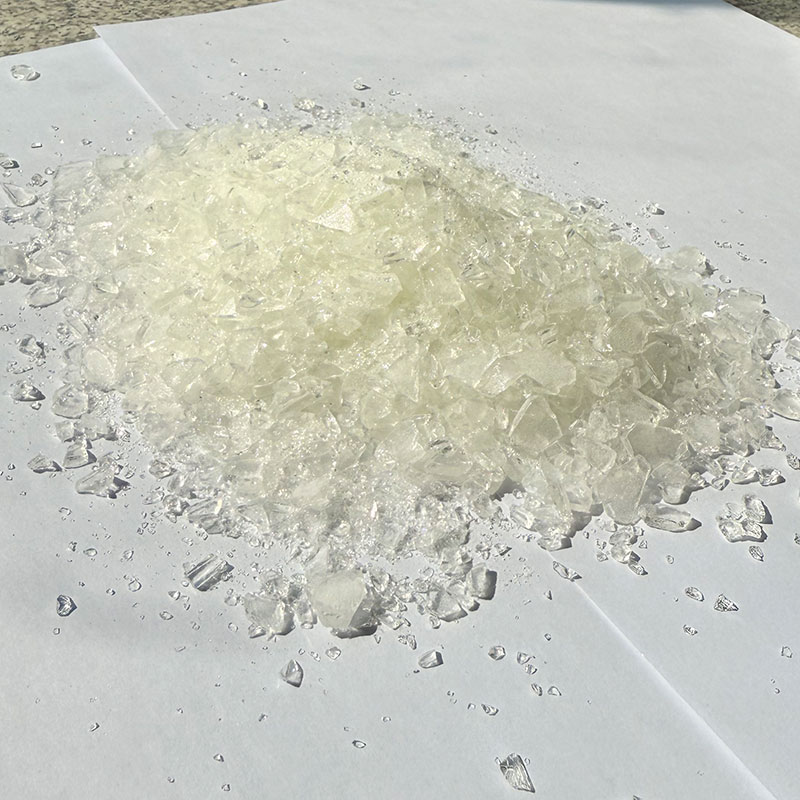

Resin

This product is a methylphenyl organosilicon resin containing silanol groups, featuring excellent compatibility and high reactivity. It can be cold blended or copolymerized to achieve high-temperature resistance. For instance, the introduction of 30% silicone can increase the continuous heat resistance of organic resins to 600℃. This silicone resin is sold in solid form in the middle and can also be directly or compounded applied to heat-resistant and weather-resistant powder coatings.

Polyester Resins

Resin

Polyester resins are essential film-forming materials widely used in powder coatings due to their excellent weatherability, stable curing behavior, and strong mechanical performance. Their molecular structure can be precisely engineered through controlled acid value, molecular-weight distribution, and end-group design, enabling balanced flow, gloss, and outdoor durability.

TGIC-Cured Polyester Resin System

Polyester Resins

TGIC-cured polyester resin systems are recognized for their outstanding outdoor durability, strong crosslink density, and long-term weather resistance. Compared with other curing technologies, TGIC systems offer a broader processing window, stable extrusion behavior, and consistent film formation even under demanding production conditions.

Primid (HAA-Cured) Polyester Resin System

Polyester Resins

Primid polyester resin systems provide an environmentally friendly curing route with zero formaldehyde release and excellent color stability.

●PCT9505 provides balanced overall performance with superior indoor durability and a clean, uniform film finish.

●PCT9106 offers a versatile curing profile, supporting high-gloss formulations with HAA or matte finishes when combined with GMA resins.

Our advantage

Proven Material Expertise

Certified Quality & Traceability

Technical Customization & Application Support

Sustainable Chemistry Commitment

Global Supply & Reliable Service

Key Applications

FAQ Use & Operation

How Does Storage Condition Affect Resin Stability?

Temperature, humidity, and inhibitor effectiveness play major roles in resin shelf life. High temperatures may cause premature crosslinking, viscosity increase, or accelerated aging. Moisture can trigger hydrolysis in certain polyester systems or reduce flow. To maintain stability, resins should be stored in cool, dry environments with effective inhibitors and proper packaging protection.

What Technical Support Do You Provide During Formulation Development?

We offer resin selection recommendations, pigment/additive compatibility checks, sample extrusion testing, and application validation to ensure reliable, scalable production.

Can You Support Custom Curing Windows for My Production Line?

Yes, we can tailor TGIC/HAA cure kinetics, adjust resin reactivity, and provide formulation guidance to match your oven temperature, line speed, and product requirements.

How Do Your Resins Help Improve Outdoor Durability?

We design polyester backbones with UV-stable structures, controlled MW distribution, and optimized end-group chemistry to enhance gloss retention and anti-yellowing performance.

What Can You Do If My Formulation Has Flow Or Leveling Issues?

Our technical team can analyze resin melt behavior, additive compatibility, and extrusion conditions to recommend an optimized resin grade or adjustment to improve surface appearance.

How Do You Ensure Batch-To-Batch Consistency for Your Resins?

We use DCS-controlled reactions, MES batch tracking, and strict acid-value/molecular-weight monitoring to guarantee stable curing performance in every production batch.